System Overview

In a way, it works like a home security system for your lab or facility, with advanced measurement and reporting capability.

In other words, it is a combination of local alarm, remote alarm + data recording system. And it is cloud based.

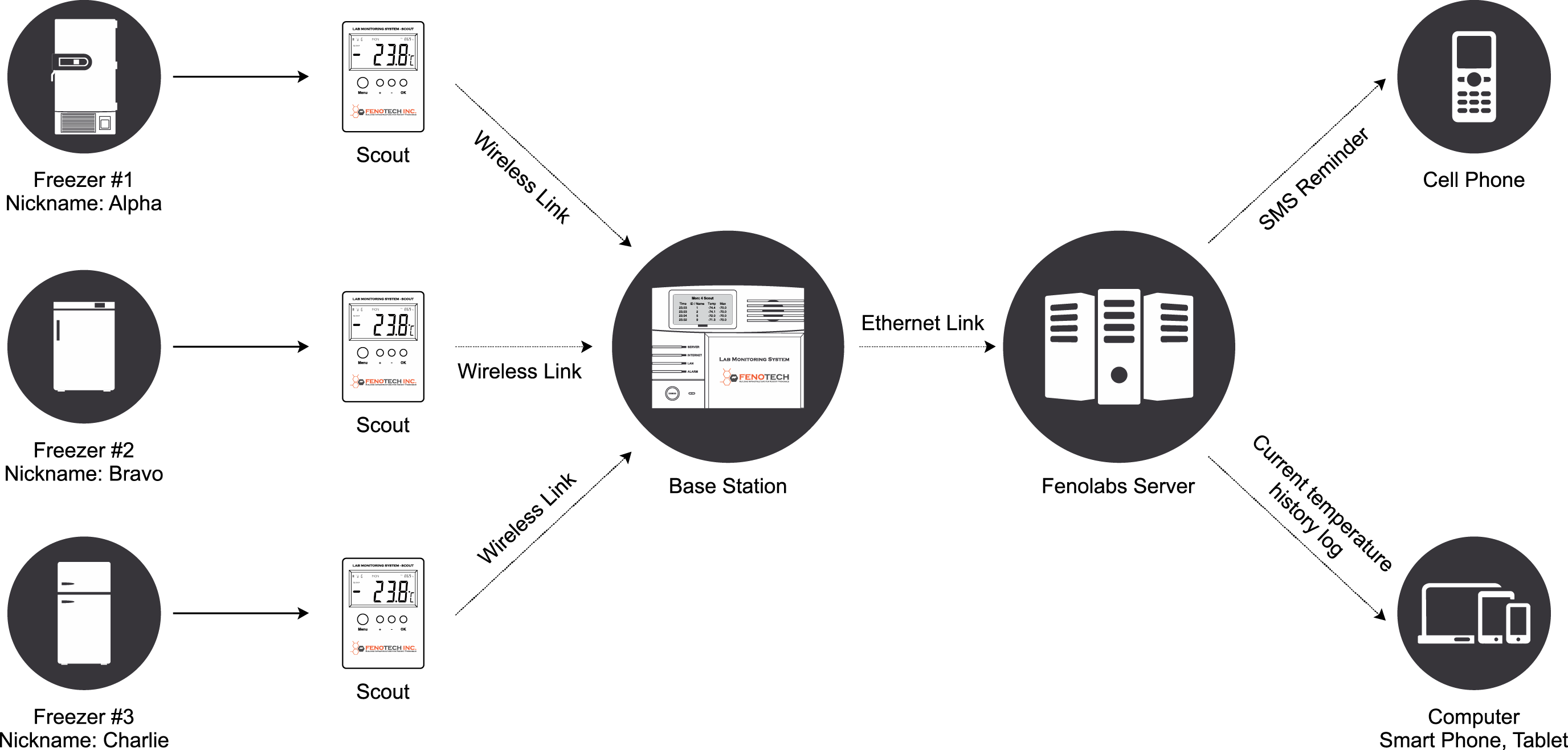

The system consists of three parts: 1) Scout modules 2) Base station 3) Fenolabs server. Scout modules are attached to your freezers, measure temperature, and send data to base station through wireless link. Base station displays temperature of each freezer and relays data to Fenolabs server through Ethernet link. Fenolabs server stores temperature data in a database & presents to you when logged in.

Scout

|

Base station

|

Backend Servers

|

Temperature Measurement

Temperature Measurement

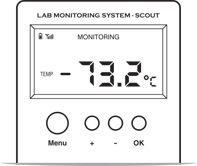

Temperature is measured by platinum Resistance-Temperature-Detector (RTD) and digitized by a 24Bit Sigma-Delta ADC. Platinum RTDs provide the highest accuracy in a range as wide as -100 - 150°C among all industrial temperature sensors. The 24Bit ADC provides a resolution of 0.025°C. The combination of platinum RTD and 24Bit ADC is typically found only in high-end precision instrument. Now we offer it to you free of charge.

Multiple measures are employed to prevent possible leakage along the sensor cable. First, cables with diameter less than 0.8mm are used to build the customized platinum RTD. As a comparison, cable diameters of typical temperature sensors are in the range of 2 - 5mm. Also a customized silicone seal is installed along the sensor cable at the edge of freezer's internal seal.

Connecting to the Cloud

Connecting to the Cloud

Temperature data are first aggregated at base station via wireless mesh network and then fed into fenolabs servers via Ethernet. The range of wireless mesh network exceeds 66ft/20m in typical laboratory settings, and can be as far as 132ft/40m if no barrier stands between scout and base station. Up to 25 scouts can connect to one base station. If your lab have more than 25 freezers or reside in multiple locations, they can be then monitored via multiple base stations. There is no limit on number of base station. Base station connects Ethernet via DHCP by default. Static IP can be also easily entered into base station. Each of our base station has its own unique MAC address assigned by IEEE Registration Authority.

Fail-safe Mechanisms

Fail-safe Mechanisms

Sophisticated fail-safe mechanisms are developed to ensure successful delivery of reminder SMS to you. For data transmission, explicit confirmation and buffering are employed at every step. When data are transmit from scout to base station, an explicit confirmation is sent back to scout from base station. If no such confirmation is received by scout, scout will send the data again. The same mechanism exists when data transmit from base station to fenolabs servers. Base station will send data again if no explicit confirmation is received. Base station buffers alarm message even when Ethernet link is unavailable when alarm is trigered and will send request for reminder SMS to fenolabs server once Ethernet connectivity is back.

Backup power systems are built in both scout modules and base stations. When the main power is unavailable, the backup battery in scout modules can provide up to 1 month’s normal use. The rechargeable Li-Ion battery in base station provides more than 8 hours use when main power is unavailable, and will be recharged when main power is back on.

As a result, reminder SMS will be sent to you immediately even when the main power is off in your lab, and will be sent to you as soon as Ethernet is back online if a threshold is breached when Ethernet is down.

To ensure service availability, three backend servers are deployed at three different geographic locations: one as main server in San Francisco, one as backup in New York, one spare server in Texas. And the web server is physically isolated from backend servers.

Installation and Setup

Installation and Setup

Our monitoring systems are preconfigured on an individual basis before shipping to you. Only minimum setup is needed from you to get them to work.

- Mount Base station at a location within 70ft/20m of all your freezers. Connect Ethernet cable and power adapter. Base station will power up automatically.

- (Optional) If a static IP is assigned by your IT administrator, enter it together with network mask and gateway into base station as instructed in user manual. Base station will reboot automatically if needed.

- Install battery and power adapter onto scout module, insert temperature sensor into freezer, insert silicone seal (unnecessary for regular refrigerators), and set temperature threshold.

- (Optional) Print your favorite image and stick it onto scout modules or your freezers if you purchased nickname package.

Now you can start to watch temperature of each freezer displayed on the LCD of base station, and on our server.

And, most importantly, you can go on vacation or go home with peace of mind. You will get SMS reminder when a threshold is breached. Don’t lose any of your valuable reagent and samples collected by hardworking!

855-628-6468

855-628-6468  925-826-3114

925-826-3114